John Norris, Head of Innovation for Samsic UK, discusses how an open approach with a clear evaluation process can keep the facilities management sector at the forefront of innovation post-pandemic.

Before March 2020, innovation within the facilities management sector was a slow and cumbersome beast. Progress was largely limited to variations on a theme upgrade to products, machinery and materials.

Then the Covid-19 pandemic struck and changed the landscape completely. Businesses across all sectors were suddenly forced to reevaluate their entire approach.

For those of us trying to lead the way in facilities management there was plenty to consider. Would people be returning to workplaces, and if so, what would that look like? Were masks and hand sanitising stations here to stay? Would our entire operation have to change?

To cope with these unprecedented new challenges, we saw an explosion of activity that we’d not previously seen, both from the usual channels but also from new entrants to the sector. Difficult circumstances have led to exciting innovations that have changed the face of facilities management for the better.

We’ve seen major developments in internet of things (IoT) sensors and connected workspaces, and the large-scale introduction of cobotics - collaborative robots designed to work closely and safely alongside humans to improve efficiency.

Restrooms equipped with footfall and proximity technology, for example, utilise data to enable on-demand cleaning. Janitorial staff are then freed up to use their skills and resources on other duties, whilst maintaining a pristine workspace for customers regardless of use and time.

Using cobots such as the ICE Phantas, which provides automated hard and soft floor cleaning, allows cleaning staff to concentrate on more critical activities, with the added benefit of helping elevate pressures on staffing.

Sustainability has sprung to the forefront of people’s minds, leading to demand for new cleaning products and technologies with the environment at their heart. Many facilities management companies are reviewing their systems, processes and supply chains to minimise their carbon footprint, and Samsic is no different.

Chemical-free cleaning systems, cleaning products using natural resources and the use of probiotics - beneficial bacteria and yeasts - are now replacing traditional chemical cleaning. Products are becoming more concentrated, helping to reduce plastic and cardboard waste as well as CO2 emissions.

Artificial intelligence (AI) is now a major global talking point. AI technology is fast becoming a staple within facilities management and is increasing in its capability exponentially. It is being used to predict and manage daily operational operations, and there is significant potential across resource planning, building management systems, recruitment and selection.

The industry has also had to innovate to deal with new flexible and hybrid working patterns, both in terms of people’s locations and working hours. Wellbeing and social mobility have become big drivers of change, and we’re seeing more demand for smart buildings with efficiencies tied to increased use of data.

It’s easy to get swept up in the excitement of all this change, with shiny new products and advanced software systems making headlines. But it’s also important to ensure that any innovation is not only suitable for the needs of the provider, but also for the needs of the client and their people. Changes need to be tested and measured to ensure that whatever is introduced is achieving the right result for all parties.

At Samsic our approach is one of ‘open innovation’. We work both internally with our own teams, and externally with suppliers and new start-ups. We feel it’s important to be early adopters and disruptors in the market, whilst staying true to our environmental and social values.

This allows us to offer our customers and our people the most efficient and productive working methodologies. We’re also lucky to be part of the much larger Samsic Group, so work collaboratively with pools of talent and expertise across 27 other countries to drive innovation.

To innovate quickly and successfully whilst minimising risk, it’s vital to share knowledge and draw on a vast array of skills, experiences and backgrounds. Operators large and small can use this approach as long as they keep a few key points in mind.

Both current and future clients value leadership and vision, so to stay at the forefront of your industry and instil confidence in both your current and future customers, speed of implementation is vitally important.

Quick and efficient integration of new technologies, products or methods enables efficiencies and benefits to be readily achieved, maximising their potential and helping to protect your business.

Speed should not come at the expense of due diligence, however. The temptation to be first on the market can be strong but it is important that any innovation, be that a product, service or a change in approach, is fully evaluated prior to its inception.

The industry is littered with equipment and machinery that seemed a good idea at the time but now lies at the back of a storage cupboard. You might grab their initial interest, but clients will soon move on if an innovation does not perform as expected - usually because it hasn’t been properly tested under suitable conditions.

I have always believed that the use of live tests is the best way to assess the performance of new innovations and minimise chances of failure.

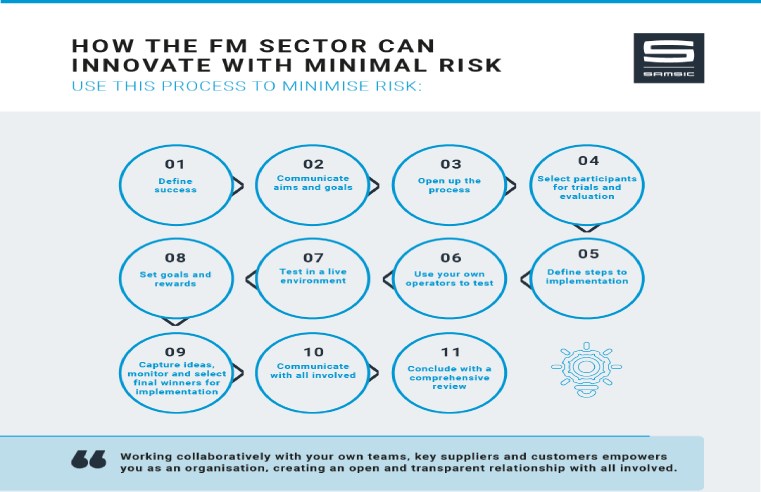

You can use this process to minimise risk:

- Start by defining what success looks like. What do you hope to achieve, and how will you measure this?

- Communicate your aims and goals with your stakeholders.

- Open up the process to your own teams and external collaborators.

- Select your participants for trials and evaluation.

- Clearly define your workflow and stages towards full implementation, including live testing.

- Live testing should be just that - live. Demonstrations are not the same thing.

- All tests and trials should be undertaken with your own operators, who are ultimately the end users for the innovation.

- Set goals and rewards for the teams working on these innovations.

- Use the process to capture ideas, monitor and select final winners for implementation or to move on from proof of concept.

- Conclude with a comprehensive review and communication with all involved.

Success is never guaranteed in this field, but by following this process you can minimise risk of failure and ensure that the innovation that does go live is fully suited to its intended use.

Working collaboratively with your own teams, key suppliers and customers empowers you as an organisation, creating an open and transparent relationship with all involved.

At Samsic we don’t see a culture resistant to change. Instead, we see a real passion from our teams to embrace new and alternative ways of working, in an environment that engages and empowers everyone to drive and impact change.